|

Buy 40ft Container Chassis Online

$7,500.00 Original price was: $7,500.00.$5,500.00Current price is: $5,500.00.

Buy 40ft Container Chassis Online

Intermodal chassis & trailers for sale.

.

Used Container Chassis Special Sales

We have in stock a large selection of container chassis and trailers in special sale in excellent condition, our chassis are carefully inspected before shipped to to our customer to ensure high quality and service. Please feel free to contact us if you have any question.

Buy 40ft Container Chassis Online

40ft Chassis & trailers

Container chassis are available in a variety of types, but the one you choose will depend heavily on your needs, budget, and shipping requirements. Such chassis can accommodate many different weight loads, as well as container sizes and types (including specialized containers).

The chassis plays an important role, as it connects and carries the weight of cargo between modes of transport.

A 40-foot container chassis is designed to carry one 40-foot shipping container over the road. Chassis are used to haul containers to and from port locations all over the United States.

Container chassis can also be utilized in the aftermarket to haul individually owned containers as well.

Many of our customers leave their container mounted on a chassis for easy re-location from one job site to the next. Containers on chassis can also be backed up directly to a loading dock, allowing for easy access to products stored in a warehouse.

The CHASSIS INDUSTRY

NEEDS AN UPDATE.

BADLY.

We’ve all read the articles over the past 11 years about the latest marine chassis crisis. We’ve all read about how far behind the United States is compared to the rest of the world with regard to chassis. We’ve all read about how truckers are dissatisfied and how there’s the constant threat of another chassis shortage bottlenecking the supply chain. The articles are great at identifying the problems and how they got started, but few offer hope for the future.

Container chassis is a specifically designed trailer frame to accommodate a wide range of container types (both standard and special boxes). It can carry any load and maneuver effortlessly. They’re available in various types, and you can choose one according to your requirement. This dynamic equipment is the support system of the entire supply chain network.

Intermodal chassis sale

Long Beach Off-coast Port offers a variety of used chassis for sale to fit every containerized load. Our used intermodal container chassis are available in major depots in North America. See locations below:

Container Chassis

Long Beach Off-coast Port was built on designing and manufacturing the lightest, strongest, and most durable Container Chassis in the industry. With hundreds of different models, our container chassis are designed to haul a variety of sizes including but not limited to 8′, 10′, 12′, 20′, 40′, 45′, 48′ and 53′. Long Beach Off-coast Port also offers hydraulic tippers that can tip up to 45 degrees. We offer tandem axle, widespread, triaxle and low deck models with a variety of options.

Long Beach Off-coast Port uses a specially engineered steel frame to reduce tare weight, increase payload, and lower operation maintenance. When producing your Container Chassis, Long Beach Off-coast Port uses the most advanced laser and plasma equipment available as well as the latest techniques in jigs and fixtures.

Tank Chassis

Long Beach Off-coast Port is known as the leading supplier of tank chassis over any other manufacturer in the intermodal industry. Over forty-five major bulk carriers and shippers utilize Long Beach Off-coast Port’s ISO tank chassis. The Long Beach Off-coast Port drop frame chassis are designed for low deck heights and higher stability.

Long Beach Off-coast Port has a variety of Tank Chassis available in various configurations including but not limited to tandem axle, tri axle, spread axle and closed tandem designs. Long Beach Off-coast Port also offers the ability to transport two 20′ ISO Tank Chassis on our Hi-Lo models.

Models

We are working to add more products to our site regularly. Long Beach Off-coast has thousands of different active models of transportation equipment to meet your requirements. Please check back often as we complete the process of adding more products.

Please feel free to contact us so we can discuss what your requirements are, and which model would best fit your specific applications.

Our chassis are well-maintained to meet Federally and locally mandated roadability laws. Our chassis were manufactured to provide high-reliability and feature components such as sealed beam LED lighting, extra-heavy-duty landing gear, specially coated brake shoes and locking mechanisms that better withstand damage.

While in service, chassis were maintained and repaired under supervision of our depot and pool technical staff to assure our customers safe and reliable service. Chassis come in sizes tailored to the containers they carry, with some chassis being adjustable for different containers.

Intermodal chassis are utilized within the shipping and railroad industries to bring containers to and from railroads and ports to the end customer. They can transport containers from trucks between ports, terminals, and warehouses, acting as a critical support in the supply chain. They are comprised of a steel frame with tires and axle systems, brakes, suspension systems, and lighting, as well as add-ons such as GPS, LED lighting, weight sensors and more.

Standard chassis can haul standard containers of 20ft to 40ft with two axles. You will need a tri-axle chassis if you intend to transport 20ft containers weighing more than 36,000 pounds or 40ft containers weighing more than 44,000 pounds.

Reasons to Buy Container Chassis

Here are the many reasons why it’s a good idea to invest in a container chassis.

1. Seamless, Secure Shipping

Containers securely attach to the chassis to ensure no movement or damage will occur. Safer transport is the name of the game!

2. Durability

While made from lightweight materials, chassis are durable and strong enough to handle the heaviest of freight.

3. Versatility

You are able to choose from many options based on your shipping preferences, needs and budget.

4. Timely Delivery

Container chassis can accommodate many containers in one trip, avoiding extra delivery charges and a tighter delivery window. This ensures a cost-effective option.

5. Ensures Customer Satisfaction

If your customers are happy with a more cost effective, timely delivery method, then you are happy! To ensure a greater customer satisfaction rating, rely on high-quality container chassis.

Types of Container Chassis

There are many different types of container chassis, including:

- 20ft Container Chassis

- 45ft Container Chassis

- 48ft to 53ft Domestic Container Chassis

- Two-axle Chassis (Common)

- Three-axle

- Four-axle

- Five-axle

- Gooseneck Chassis

- Extendable

- Combo

- Heavy-duty

- Lightweight

- Rear B-Train

- Straight Frame

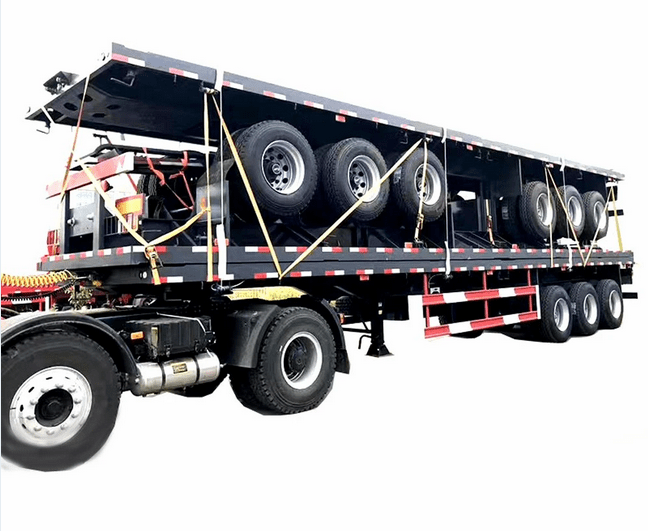

- Flatbed Container Trailer

Factors in Choosing the Right Chassis

There are many things to take into consideration before you choose a chassis, such as:

- Industry-specific usage and requirements

- Number of axles and weight threshold

- Incurred costs

Contact Tropical Trailer Leasing

If you have additional questions about container chassis, or you would like to rent, buy or lease a storage trailer, contact us today for a free quote. Our company can meet your exact needs, whether you need one unit or hundreds,

What is a container chassis?

In simple terms, a container chassis or intermodal chassis is a wheeled structure designed to carry containers via trucks between terminals, warehouses, and ports. A chassis composes of a steel frame with tires and axle systems. It also includes suspension, brakes, and lighting mechanisms.

With the advancement of technology, newer models come with features such as ABS, weight sensors, LED lights, and GPS tracking systems. It’s an effortless way to carry or move shipping containers. They play a key role in making transportation easy and efficient.

A standard chassis transports standard ISO containers (20ft and 40ft) with two axles. Generally, a tri-axle chassis is needed to carry 20ft containers above the weight of 36,000 lbs or 40ft containers above 44,000 lbs.

You can choose different types and sizes of container chassis depending on your requirements.

Why do you need a container chassis?

Container chassis, the wheeled equipment, increases movement speed and efficiency. Chassis are designed in a way that they can separate from the truck to accommodate different kinds of containers easily. Let’s take a quick look at some of the reasons why you need a container chassis in your shipping process.

1. Smooth and secure shipping

Containers are securely attached to the chassis. It prevents unnecessary container movements – ensuring safer transportation.

2. Durability and easy transportation

They are usually made out of lightweight materials but are durable enough to hold heavy load containers with ease.

3. Suits different shipping requirements

Container chassis come in different types. Companies can choose from a wide range of options based on their specific needs. You’ll read more about the types further down the blog.

4. Quick, cost-effective, and offers timely delivery

Container chassis can load several containers at the same time – making the process quick and efficient. This, in turn, fastens delivery and the risk of extra charges for your shipment due to untimely delivery is reduced.

5. Uplifts customer satisfaction

When you’re so quick, efficient, and safe in shipping the containers, it’s obvious that your customers are delighted. It improves reliability and the overall customer experience.

Even though container chassis help you become more efficient and on time, unexpected things do happen. Things, that can make the containers late – if they’re rolled, stuck at port, or even unloaded at the wrong port. Thus, it’s a good idea to get your hands on a SOC container

Most commonly used types of container chassis

There are 3 commonly used container chassis. These chassis make loading and unloading of containers easy. They’re also designed to adapt to the different sizes of containers. Take a look at these chassis.

Tilt container chassis

Tilt container chassis makes it easy to unload a container. There is an apparatus attached to the chassis with a pivot device to make loading and unloading simple. Unlike the conventional chassis, this one has upper and lower frames attached to it. There’s a hydraulic system on the upper frame that tilts upward. You’ll also find a roller at the upper frame that connects to the lower frame of the chassis. This whole arrangement of the chassis makes the process of loading and unloading secure and easy to handle. A special design like these costs more money, but if convenience is what you choose, go for this one.

Extendable container chassis

Extendable, as the name suggests, this chassis type can adapt to any container size. It works similar to a regular chassis but is extendable at the back. By doing so, bigger containers are mounted hassle-free. You can go for this type of chassis if you have varying container lengths to transport. Extendable chassis help you transport sealed containers across different countries and states without any hiccups.

Tip: Remember that the length of the chassis should be greater than the size of the container. Place the load/container at the center to keep the trailer stable and balanced.

Common container chassis

This type of container chassis comes without any modification or sophistication. It’s a simple fixed structure to carry and transport containers from one place to another. Overhead cranes are used during the loading and unloading process. You can use a common container chassis to transport 20ft, 40ft, or 45ft containers. These chassis have visibly marked spots to help identify the position where the containers need to be placed securely. Common container chassis are affordable and pretty easy to use. However, you may end up paying extra for external equipment such as overhead cranes.

Different container chassis models in the market

Depending on your shipping requirements and, of course, the container size, there are several types of chassis available in the market. Let’s take a look at them.

Chassis type by dimension

- 20ft container chassis

- 40ft – 45ft container chassis

- 48ft to 53ft domestic container chassis

Chassis type by purpose

- Generator chassis

- All chassis model

- Tank chassis

- Flatbed chassis

Chassis type by feature/design

- Gooseneck chassis

- Extendable chassis

- Heavy-duty chassis

- Lightweight chassis

- Combo chassis

- Rear B-train chassis

- Straight frame chassis

- Canadian Chassis

How to choose the right container chassis?

By now, you already have an idea about container chassis and the different types. But along with that, you must also know which container chassis is suitable for you. Choosing the ideal one largely depends on your requirements. Businesses can choose what’s best and affordable for their daily operations.

Having an idea of how to choose a container chassis will help ensure that your containers go through a smooth loading and unloading process. It’ll also save you a few extra dollars. You can consider the following factors:

Usage and requirements (Industry-specific)

If you only need to transport containers, chassis modeled specifically for containers are the best. But, if you need to move other types of cargo, go for a flatbed container chassis trailer – as it serves a dual purpose. If you need to load/unload cargo at specific places, a tilt chassis is a great choice.

Number of axles/ weight threshold

You can choose the number of axles in the chassis depending on the cargo or container weight. Remember: the more the number of axles, the more the load capacity it can hold. For daily usage, 2 or 3 axle chassis is your best choice.

Costs incurred

Consider your container specifications and requirements before choosing a chassis. Usually, a specialized chassis costs higher than the regular ones.

What is a container chassis?

In simple terms, a container chassis or intermodal chassis is a wheeled structure designed to carry containers via trucks between terminals, warehouses, and ports. A chassis composes of a steel frame with tires and axle systems. It also includes suspension, brakes, and lighting mechanisms.

With the advancement of technology, newer models come with features such as ABS, weight sensors, LED lights, and GPS tracking systems. It’s an effortless way to carry or move shipping containers. They play a key role in making transportation easy and efficient.

A standard chassis transports standard ISO containers (20ft and 40ft) with two axles. Generally, a tri-axle chassis is needed to carry 20ft containers above the weight of 36,000 lbs or 40ft containers above 44,000 lbs.

You can choose different types and sizes of container chassis depending on your requirements.

Why do you need a container chassis?

Container chassis, the wheeled equipment, increases movement speed and efficiency. Chassis are designed in a way that they can separate from the truck to accommodate different kinds of containers easily. Let’s take a quick look at some of the reasons why you need a container chassis in your shipping process.

1. Smooth and secure shipping

Containers are securely attached to the chassis. It prevents unnecessary container movements – ensuring safer transportation.

2. Durability and easy transportation

They are usually made out of lightweight materials but are durable enough to hold heavy load containers with ease.

3. Suits different shipping requirements

Container chassis come in different types. Companies can choose from a wide range of options based on their specific needs. You’ll read more about the types further down the blog.

4. Quick, cost-effective, and offers timely delivery

Container chassis can load several containers at the same time – making the process quick and efficient. This, in turn, fastens delivery and the risk of extra charges for your shipment due to untimely delivery is reduced.

5. Uplifts customer satisfaction

When you’re so quick, efficient, and safe in shipping the containers, it’s obvious that your customers are delighted. It improves reliability and the overall customer experience.

Even though container chassis help you become more efficient and on time, unexpected things do happen. Things, that can make the containers late – if they’re rolled, stuck at port, or even unloaded at the wrong port. Thus, it’s a good idea to get your hands on a SOC container

Most commonly used types of container chassis

There are 3 commonly used container chassis. These chassis make loading and unloading of containers easy. They’re also designed to adapt to the different sizes of containers. Take a look at these chassis.

Tilt container chassis

Tilt container chassis makes it easy to unload a container. There is an apparatus attached to the chassis with a pivot device to make loading and unloading simple. Unlike the conventional chassis, this one has upper and lower frames attached to it. There’s a hydraulic system on the upper frame that tilts upward. You’ll also find a roller at the upper frame that connects to the lower frame of the chassis. This whole arrangement of the chassis makes the process of loading and unloading secure and easy to handle. A special design like these costs more money, but if convenience is what you choose, go for this one.

Extendable container chassis

Extendable, as the name suggests, this chassis type can adapt to any container size. It works similar to a regular chassis but is extendable at the back. By doing so, bigger containers are mounted hassle-free. You can go for this type of chassis if you have varying container lengths to transport. Extendable chassis help you transport sealed containers across different countries and states without any hiccups.

Tip: Remember that the length of the chassis should be greater than the size of the container. Place the load/container at the center to keep the trailer stable and balanced.

Common container chassis

This type of container chassis comes without any modification or sophistication. It’s a simple fixed structure to carry and transport containers from one place to another. Overhead cranes are used during the loading and unloading process. You can use a common container chassis to transport 20ft, 40ft, or 45ft containers. These chassis have visibly marked spots to help identify the position where the containers need to be placed securely. Common container chassis are affordable and pretty easy to use. However, you may end up paying extra for external equipment such as overhead cranes.

Different container chassis models in the market

Depending on your shipping requirements and, of course, the container size, there are several types of chassis available in the market. Let’s take a look at them.

Chassis type by dimension

- 20ft container chassis

- 40ft – 45ft container chassis

- 48ft to 53ft domestic container chassis

Chassis type by purpose

- Generator chassis

- All chassis model

- Tank chassis

- Flatbed chassis

Chassis type by feature/design

- Gooseneck chassis

- Extendable chassis

- Heavy-duty chassis

- Lightweight chassis

- Combo chassis

- Rear B-train chassis

- Straight frame chassis

- Canadian Chassis

How to choose the right container chassis?

By now, you already have an idea about container chassis and the different types. But along with that, you must also know which container chassis is suitable for you. Choosing the ideal one largely depends on your requirements. Businesses can choose what’s best and affordable for their daily operations.

Having an idea of how to choose a container chassis will help ensure that your containers go through a smooth loading and unloading process. It’ll also save you a few extra dollars. You can consider the following factors:

Usage and requirements (Industry-specific)

If you only need to transport containers, chassis modeled specifically for containers are the best. But, if you need to move other types of cargo, go for a flatbed container chassis trailer – as it serves a dual purpose. If you need to load/unload cargo at specific places, a tilt chassis is a great choice.

Number of axles/ weight threshold

You can choose the number of axles in the chassis depending on the cargo or container weight. Remember: the more the number of axles, the more the load capacity it can hold. For daily usage, 2 or 3 axle chassis is your best choice.

Costs incurred.

Consider your container specifications and requirements before choosing a chassis. Usually, a specialized chassis costs higher than the regular ones.

Related products

Container Chassis